How Radon Mitigation Systems Work: Types, Components & Installation

Radon mitigation systems are engineered solutions that reduce indoor concentrations of radon, a colorless, odorless radioactive gas produced by the decay of uranium in soil and rock. These systems work by changing pressure relationships between a building and the underlying soil—typically creating negative pressure below the foundation so soil gas is drawn away and vented safely above the roofline—thereby protecting occupants from chronic radon exposure and the associated lung cancer risk. This guide explains how radon mitigation systems work, compares the most effective system types such as active soil depressurization and sub-membrane depressurization, breaks down component selection and installation practices, and describes maintenance and local considerations for Denver-area homes. Homeowners will learn where radon comes from, why mitigation is essential at or above the EPA action level, how professionals design and size systems for different foundations, and what routine checks ensure long-term performance. The next section defines radon and the clinical thresholds that prompt remediation, which leads directly into the practical design guidance you can use to evaluate mitigation options.

What Is Radon and Why Is Mitigation Essential?

Radon is a colorless, odorless, radioactive gas measured in picocuries per liter (pCi/L) that enters buildings from the soil and accumulates in enclosed spaces, increasing long-term lung cancer risk. The mechanism driving indoor radon accumulation is pressure-driven soil gas migration: lower indoor pressure relative to the soil draws radon-bearing air through cracks, joints, and openings in foundations, where it concentrates unless actively vented. The EPA action level of 4.0 pCi/L is the remediation trigger because epidemiological studies show that sustained exposures above this level substantially increase lung cancer incidence; mitigation commonly reduces concentrations well below this threshold. Homeowners should act on test results at or above the EPA action level and consider mitigation measures when levels approach that trigger, since many systems routinely reduce levels to below 2.0 pCi/L after installation. Understanding how radon enters a home and what counts as elevated exposure sets the stage for selecting appropriate mitigation strategies and ensures homeowners connect risk awareness to actionable remediation.

Radon presents a measurable public-health burden, especially for smokers and occupants with long-term exposure. The next subsection details the specific health impacts and vulnerable populations to clarify urgency and risk modifiers.

H3: What Are the Health Risks of Radon Exposure?

Radon exposure is the second leading cause of lung cancer after smoking and represents a cumulative, dose-dependent carcinogenic risk as established by major public-health agencies. Long-term inhalation of radon decay products delivers alpha radiation to lung tissue, which damages DNA and increases the probability of malignant transformation; combined exposure with tobacco smoke multiplies risk substantially. Vulnerable populations include smokers, long-term residents, and those with compromised respiratory health, and risk increases with both concentration (pCi/L) and duration of exposure. Current research shows that reducing indoor radon translates directly into lower lifetime lung cancer risk for household members, so mitigation is a primary preventive measure for residential safety. These health risk considerations lead naturally to an examination of how radon physically migrates into buildings and which entry points installers target when designing a system.

H3: How Does Radon Enter Homes?

Radon migrates from soil into buildings through pressure-driven flow and diffusive movement, exploiting openings such as cracks in slabs, gaps around service penetrations, cold joints, sump pits, and porous concrete. The primary driver is the pressure differential between the indoor environment (often lower) and the soil gas, causing air and radon to move upward into the structure; stack effect and mechanical ventilation can exacerbate this. Different foundation types present specific entry behaviors: slab-on-grade homes typically have slab cracks and utility penetrations as dominant paths, basements introduce additional perimeter and floor-wall joint exposures, and crawl spaces often produce whole-house pressure interactions if unsealed. Identifying dominant entry points during a diagnostic assessment allows designers to place suction points and sealing measures efficiently to intercept soil gas and optimize mitigation performance. With entry paths mapped, technicians choose the most effective mitigation strategy for the foundation type and local soil conditions.

Which Types of Radon Mitigation Systems Are Most Effective?

Mitigation system selection hinges on foundation type, soil permeability, and the measured radon concentration; the most effective and widely applicable approach for existing homes is active soil depressurization (ASD), which uses a dedicated fan to extract soil gas from beneath slabs or drain tiles and vent it safely above the roofline. ASD variants include sub-slab depressurization (SSD) for concrete slabs and sub-membrane depressurization for crawl spaces where a vapor barrier is used to collect soil gas; passive systems and whole-house ventilation upgrades serve as adjuncts or new-construction strategies but typically deliver lower, less predictable reductions in existing structures. System choice balances effectiveness, visual impact, cost, and homeowner priorities: ASD generally yields the largest and most reliable reductions, while encapsulation and ventilation can complement ASD in crawl-space or high-humidity situations.

Different system types fit different foundations and performance requirements:

This comparison shows ASD approaches are generally preferred for reliable reduction; the next subsections explain ASD mechanics and alternative methods in detail and then connect system choice to practical customization options.

H3: How Does Active Soil Depressurization Work?

Active soil depressurization works by installing one or more suction points beneath the slab or under a vapor barrier, connecting these points with PVC piping to an in-line or exterior-mounted fan that draws soil gas from beneath the foundation and discharges it above the roofline. The fan continuously maintains negative pressure in the collection zone so that soil gas moves into the system rather than into the living space, and the vent stack elevates exhaust to reduce re-entry risk and disperse radon safely into the outdoor air. Installation typically includes sealing major slab openings to strengthen the depressurization field, and a manometer is used to verify suction and ongoing system performance.

By creating a controlled flow path for soil gas, ASD is the most reproducible method to lower indoor radon concentrations across foundation types.

H3: What Are Other Radon Mitigation Methods?

Alternative and adjunct methods include crawl space encapsulation with sub-membrane depressurization, increased ventilation strategies such as heat-recovery ventilators (HRVs) or exhaust fans, and targeted sealing combined with passive stacks in new construction. Each approach has tradeoffs: encapsulation plus SMD is effective for crawl spaces but requires durable membrane installation and moisture control; ventilation can dilute radon but may raise energy use and humidity control issues; passive stacks are low-cost in new builds but normally need a fan retrofit for consistent performance in existing homes. In many cases, combining methods—such as sealing and encapsulation plus ASD—yields the best long-term outcome for both radon reduction and indoor air quality. Understanding these pros and cons helps match mitigation tactics to site constraints and homeowner priorities.

However, it’s crucial to acknowledge that while depressurization is effective for radon, it can introduce other challenges, particularly concerning moisture management in certain foundation types.

Radon Depressurization: Preventing Intrusion & Managing Moisture

Purpose of the depressurization is to prevent the intrusion of radon or other insanitary particles into indoor air. However, in typical foundation structures the depressurization will cause airflow from soil into the crawl space air and it may convey excessive moisture making the hygrothermal conditions potential for mould growth or other moisture-induced biological damage, which is not considered to be acceptable even with the depressurization.

Numerical study of time-dependent hygrothermal conditions in depressurized crawl space, J Vinha, 2018

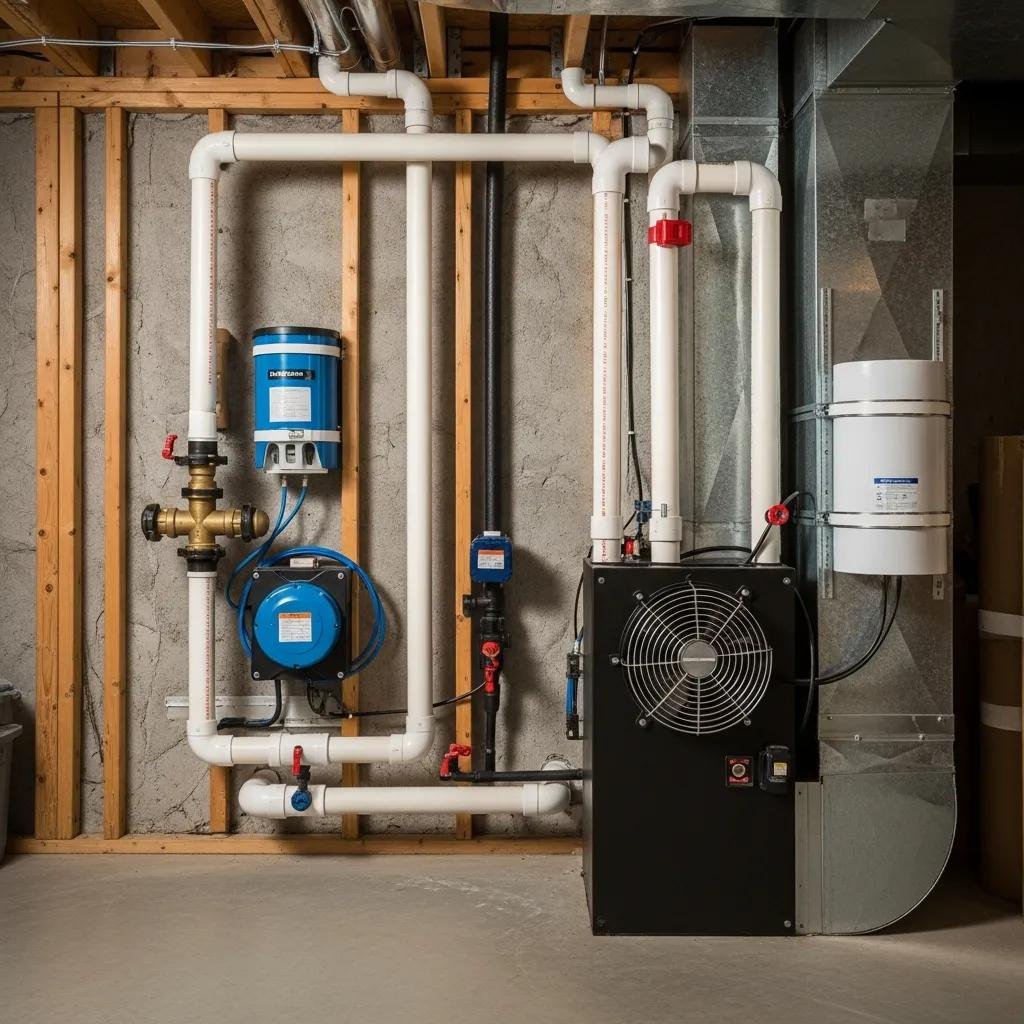

What Are the Key Components of a Radon Mitigation System?

A typical radon mitigation system comprises a radon fan, PVC vent piping, suction pits or drilled collection points, sealing materials, and monitoring devices such as manometers or continuous radon monitors that verify ongoing performance. Each component plays a specific role: the fan provides suction and flow; the piping routes soil gas to a safe exhaust point; the collection point gathers soil gas efficiently; seals prevent bypass leakage; and a manometer or monitor indicates whether the system is maintaining the required negative pressure. Component sizing and placement—fan capacity (CFM), pipe diameter and route, suction-point spacing, and acoustic isolation—determine system effectiveness, noise profile, and longevity.

Key system components and their primary functions:

- Radon Fan: Moves soil gas from the collection point through the piping and out of the building.

- PVC Vent Piping: Provides a continuous, sealed path from the suction point to the roof exhaust.

- Suction Pit / Collection Point: The entry zone beneath slab or membrane where soil gas is collected.

- Sealing Materials: Caulk, epoxy, and membrane used to reduce uncontrolled leakage paths.

- Manometer / Monitor: A diagnostic device indicating system suction and functioning status.

H3: How Do Radon Fans Function and What Types Are Available?

Radon fans are axial or centrifugal units designed to operate continuously and maintain a pressure field that draws soil gas away from the building interior; selection depends on required vacuum (negative pressure) and flow (CFM) while balancing noise and energy use. Common fan categories include in-line (mounted in attic or exterior), external weatherproof fans, and higher-suction models for low-permeability soils; each has different installation constraints related to roof penetrations, attic access, and vibration isolation. Expected lifespan typically ranges across industry norms, and signs of fan degradation include reduced manometer reading, increased vibration, and audible changes; fan placement and proper vibration damping reduce noise complaints. Evaluating fan noise (dBA), airflow, and duty-cycle expectations guides technicians in choosing a model that provides dependable soil gas removal while preserving homeowner comfort.

A summary of fan options and selection criteria guides the next discussion on piping, suction points, and monitoring.

H3: What Roles Do PVC Piping, Suction Pits, and Manometers Play?

PVC piping forms the sealed pathway that safely conveys soil gas from the suction pit to an elevated exhaust location, and routing best practices include continuous upward run to roof termination, minimal elbows, and secure joints to avoid leaks. Suction pits or drilled suction points create the collection zone beneath the slab or membrane; installers choose between core-drilled pits, existing sump modifications, and distributed floor saw cuts depending on access and soil spread. Manometers provide a simple, visual indicator of differential pressure across the system; a stable reading within the expected range signals normal operation while a falling needle warns of disconnection or fan failure. Together, proper piping, well-placed suction points, and reliable monitoring form the operational backbone of an effective mitigation system.

How Is a Radon Mitigation System Installed?

Installation begins with pre-install diagnostic testing and a walkthrough to map entry points and foundation conditions, followed by creating suction points, routing piping, mounting the fan, sealing leaks, and performing post-install verification testing to confirm target reductions. Design choices are guided by soil permeability, foundation layout, and practical constraints like attic space or roof penetrations; sizing fans and choosing suction-point locations are part of initial system design. Safety and code compliance—proper electrical connections, roof flashing for vent stacks, and secure mounting—are integral to durable installations, and a manometer is installed for ongoing homeowner monitoring. After the mechanical work, post-mitigation testing (short-term or long-term) validates performance and ensures indoor concentrations meet remediation goals.

Martens Radon follows a transparent on-site process when providing local services: technicians offer a free on-site assessment, provide a firm price in writing the same day of the visit, and support independent post-test options and lifetime workmanship coverage while they’re in business. This operational transparency helps homeowners understand expected costs and confirms performance after installation.

The next subsection lays out the step-by-step installation sequence in a numbered format for clarity and HowTo optimization.

H3: What Is the Step-by-Step Installation Process?

- Diagnostic assessment and pre-test: Measure baseline radon and inspect foundation for entry points.

- Design and mark suction locations: Identify one or more collection points based on foundation and soil.

- Create suction pit(s): Core-drill slab or prepare membrane collection area; install gravel if needed.

- Install PVC piping and seal penetrations: Route piping to a high exhaust point and seal slab openings.

- Mount fan and connect power: Secure fan in attic/exterior with vibration isolation and correct electrical hookup.

- Install manometer and perform post-test: Verify suction, run diagnostic tests, and measure post-install radon levels.

Estimated time for a standard retrofit is typically completed in a single day for common slab foundations, and safety checks such as electrical verification and roof flashing inspections are performed before handover. This ordered approach leads into how systems are tailored for different foundation types in the next subsection.

H3: How Are Systems Customized for Different Home Foundations and Layouts?

Systems are customized by matching suction-point strategy, fan capacity, and routing to foundation type: single-point SSD works for small, low-leakage slabs, multiple suction points or a distributed pipe network is used for large slabs or homes with drain tile, and sub-membrane systems are applied with full encapsulation in crawl spaces. Soil permeability and the presence of drain tiles or sump pits often determine whether a single fan will suffice or whether increased CFM or multiple fans are necessary; installers use manometer response and diagnostic smoke tests to confirm the effective depressurization field. Routing decisions—attic vs. exterior mounting, roof penetration locations, and aesthetic pipe runs—balance performance, noise, and homeowner appearance concerns. These customization rules-of-thumb inform installers’ real-time choices to achieve sustained reduction while minimizing disruption.

How Should Radon Mitigation Systems Be Maintained for Longevity and Effectiveness?

Routine maintenance consists of simple homeowner checks combined with periodic professional inspections to ensure continuous performance and to detect wear in fans, piping, and seals before they cause elevated readings. Homeowners should visually inspect pipe runs and exterior fan mounts monthly, observe manometer position for consistent suction, and listen for abnormal fan noise that could indicate motor or bearing issues. Industry practice recommends annual professional inspections to verify wiring, mounting hardware, and system integrity, and a typical fan replacement window falls in the multi-year range depending on model and duty cycle; service intervals should be set based on observed performance trends. Continuous monitoring options or periodic post-mitigation testing provide assurance that indoor levels remain low and offer data for proactive maintenance decisions.

A practical homeowner checklist and a maintenance-schedule table below give actionable guidance for routine and professional tasks.

- Inspect the manometer: Confirm the needle remains in the expected range.

- Visual pipe check: Look for cracks, disconnections, or weather damage at exterior runs.

- Listen for fan changes: Note unusual sounds, increased vibration, or intermittent operation.

- Confirm exhaust clearance: Ensure roof exhaust remains unobstructed and visible from a distance.

These monthly checks are the front line of performance assurance and lead directly to the recommended professional maintenance schedule.

H3: What Routine Checks Should Homeowners Perform?

Homeowners should perform a concise monthly checklist that focuses on observable indicators of system health: verify the manometer needle remains within the expected suction band, scan the visible length of PVC piping for cracks or loose joints, confirm the exterior fan assembly is secure and free of debris, and note any new interior musty odors or moisture that could signal leaked soil gas or plumbing issues. If the manometer shows a steady decline or the fan produces grinding noises, homeowners should contact a licensed technician for diagnostic evaluation and potential repairs. Maintaining basic records of inspections and any post-test results helps professionals spot gradual declines and plan preventative maintenance decisions. Routine homeowner vigilance is simple but crucial to ensuring the system continues protecting occupants from radon exposure.

H3: When and How Should Radon Fans Be Replaced or Serviced?

Fans typically run continuously and are rated for long operational life, but they can fail or lose efficiency due to motor wear, bearing failure, or moisture intrusion; common replacement windows range broadly and are influenced by model quality, installation environment, and duty cycle. Signs that service or replacement is needed include persistent drops in manometer reading, unusual vibration or noise, or visible corrosion and water ingress; when these occur, a licensed mitigation professional should perform diagnostics, measure airflow and suction, and recommend fan replacement if repairs are insufficient. Fan replacement follows safe electrical isolation, correct fan selection to match system resistance, and post-replacement verification testing to ensure the new unit achieves the target depressurization and radon reduction. Proper servicing preserves system performance and avoids lapses that could expose occupants to elevated radon.

Regular maintenance and timely fan service ensure mitigation longevity and lead naturally into local considerations that influence design and expectations in the Denver metro area.

What Local Factors Affect Radon Levels and Mitigation in the Denver Metro Area?

Local geology, soil composition, and foundation practices in the Denver metro area and foothills influence typical radon readings and how systems are designed, with regional variations affecting required suction, number of suction points, and expectations for post-mitigation levels. The Denver foothills’ bedrock and soil heterogeneity can create high spatial variability; some properties measure modest levels while neighboring lots may record significantly higher concentrations, so on-site testing is essential to guide system design. Technicians working locally tune fan sizing and suction layouts to address soil permeability variations common in the region, and homeowners should expect post-mitigation readings to typically fall below 2.0 pCi/L after properly designed ASD installations. Local knowledge of soil and foundation idiosyncrasies helps shape realistic expectations for cost, routing, and system footprint.

H3: What Are Typical Radon Levels in Denver and Foothills?

Measured radon concentrations in the Denver metro area and foothills vary widely depending on local geology, but many regional surveys and testing programs have found frequent readings both below and above the EPA action level, emphasizing that geography alone cannot replace direct testing. Typical observed ranges often span from low single digits to values exceeding the EPA action level in localized pockets, and post-mitigation results commonly show reductions to below 2.0 pCi/L when ASD is correctly implemented. Because levels can change with seasonal pressure differences and home modifications, both initial testing and post-mitigation retesting are essential components of a robust mitigation program. These regional patterns underscore the need for licensed local technicians who understand how local soil and foundation types influence system design.

H3: How Does Martens Radon Provide Expert, Licensed Mitigation Services Locally?

Martens Radon is a Colorado-licensed radon mitigation provider (License RMT.0000225) serving the Denver metro area and foothills with hands-on residential expertise informed by 25 years of residential construction experience. The company emphasizes straightforward, homeowner-friendly practices: a free on-site assessment to evaluate foundation and soil conditions, a firm price provided in writing the same day of the visit so there are no surprise up charges later, and pricing transparency with expert radon mitigation in Denver Metro starting at approximately $1,400 for a standard retrofit system as stated. Martens Radon installs quiet, reliable systems that protect families and preserve home appearance, offers independent post-test options to verify results, and provides lifetime workmanship coverage while they’re in business to reinforce long-term trust.

These credentials and service commitments help local homeowners connect technical mitigation needs to a licensed, locally experienced provider for testing, installation, and verification.

This final local positioning ties the technical guidance in this guide to actionable local service options and encourages homeowners to pair thorough testing with professionally executed mitigation.